Emission Evaluation¶

The rs_emission addin supports the following tests

WHTC

WHSC

ETC European transient cycle

ESC European steady state cycle

NRTC Nonroad Transient Cycle (NRTC) Test

NRSC

WHSC + WNTE

WNTE

FTP HD US Heavy Duty Federal Test Procedure (FTP) Test

JE05 Japanese JE05 Emissions Test Cycle

ELR European load response test

EPA 1065

The addin is not part of the standard UniPlot installation.

To start an evaluation choose Emission Evaluation=>Evaluation.

Installation¶

Create a sub directory rs_emission in the directory

uniplot\addin. Copy the following files into the directoryuniplot\addin\rs_emission:etc_dialog.ic etc_emissions.ic etc_init.ic etc_loaddata.ic etc_main.ic etc_refcycle.ic etc_template.ic etc_validation.ic etc_WHSC.ic rs_emission.icl etc_template_en.ipw

Copy the

rs_emission.adiintouniplot\addin.Copy the file

etc_weightfactor.inionto your hard drive.Start UniPlot.

Choose Tools=>Add-In Manager. Mark the addin “Emission-Test Evaluation”.

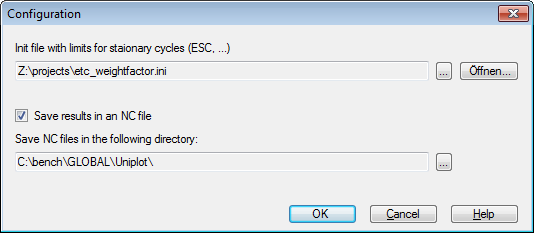

Choose Emission Evaluation=>Configuration and select the file

etc_weightfactor.ini.

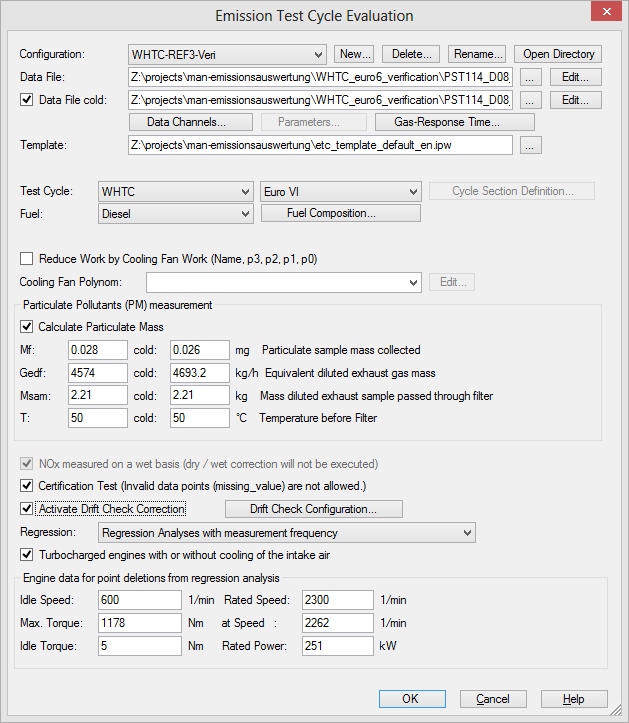

Main Dialog¶

- Configuration

Displays a list of configurations. A configuration contains all settings. Click on the New button to create a new configuration.

- Data File

To open a new data file click on the … button.

- Data File Cold

For the WHTC, NRTC or the FTP-HD a cold data file can be selected.

- Data Channels

Click this button to select the necessary channels. See Data Channels.

- Gas-Response Time

For transient tests the gas response time can be specified. See Gas Response Time.

- Template

Click on the … button to select a template. The default template is

\uniplot\addin\rs_emission\etc_template_en.ipw. See Template.

- Test Cycle

List of supported cycles.

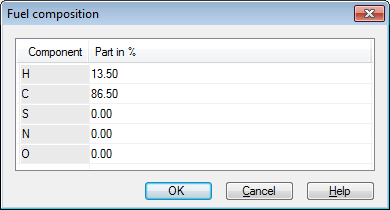

- Fuel

List of supported fuels. This version supports only Diesel. The fuel composition can be set. See Fuel Composition.

Reduce Work by Cooling Fan Work

Calculate Particulate Mass

Data for full flow dilution system. GEDF is directly measured by the CVS equipment:

PTMass = Mf / Msam * Gedf * x / 1000 x = test length in hours (1 for stationary tests)

Value

Description

Mf

Is the particulate mass sampled over the cycle in milligrams.

Msam or msep

Is the mass of diluted exhaust gas passing the particulate collector filters in kilograms.

Gedf or medf

Is the mass of equivalent diluted exhaust gas in kg/h. If the mass is only given in kg/test it must be converted to kg/h.

NOx-Measurement wet

If this option is selected the dry/wet correction is not applied. If the option is not selected the correction factor as defined in ISO 16183, Formula 14 is applied to the NOx data channel.

Certification Test

If this option is selected, all data points for all specified channels must be valid. The length of the data may be 5 seconds shorter than the length specified in the law (Example: The WHTC length is 1800 s. The data for the WHTC must be at least 1795 s long. If the option is not selected, the following limits must be met:

50% of all values must be valid.

The time length of an invalid section is limited to 10 seconds.

Only 10% of all data points of a single channel may be invalid.

Turbocharged engine

Is used to calculate the engine test conditions fa. For a test to be recognized as valid, the parameter fa shall be such that:

0.96 < fa < 1.06.

- Engine Data

The power, torque and speed information are used to calculate the validation statistics of the test cycle.

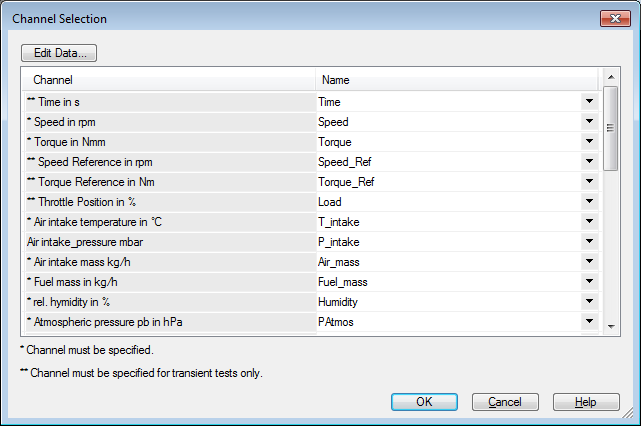

Data Channels¶

The button Data Channel opens the following dialog box:

In the channel selection dialog box, the mandatory channels for the selected emission cycle must be specified. To select a channel, open the combo box or type in the name of the channel. Some channels are optional. Unused channels can be marked as –Not Used–.

Channels:

Channel |

Unit |

Description |

|---|---|---|

Time |

s, ms |

Used for transient cycle (WHTC, NRTC, ETC, WHSC etc.). If specified in ms the unit name must be ms. |

Speed |

rpm |

Actual Speed |

Speed Reference |

rmp |

Reference Speed. |

Torque |

Nm |

Actual Torque |

Torque Reference |

Nm |

Reference Torque for transient cycles. |

Air Intake Temperature |

°C |

Temperature of the intake air. |

Air intake pressure |

mbar |

Used to calculate the absolute humidity of the intake air (g water per kg dry air) if the relative humidity is measured in the intake manifold. If set to –Not Used–, the pressure will be set to 0. |

Air intake mass flow rate |

kg/h |

|

Fuel mass flow rate |

kg/h |

|

rel. humidity |

% |

Relative humidity. |

Atmospheric pressure |

hPa / mbar |

Atmospheric pressure |

CO2 |

% |

Carbon dioxide, measured dry. |

CO |

ppm |

Carbon dioxide, measured dry. |

NOx |

ppm |

Carbon dioxide, dry or wet measured. |

HC |

ppm |

Carbon dioxide, wet measured. |

Smoke (AVL 439 Opacimeter) |

% |

Optional |

Throttle in % |

% |

Used to define full load and idle for the regression anal |

CH4 in ppm |

ppm |

Methane |

NMHC in ppm |

ppm |

Non-methane hydrocarbons |

Alternative to pb: Dew Point Temperature in °C |

°C |

|

Smoke (AVL 439 Opacimeter) |

K |

|

Smoke (AVL 483 Micro Soot Sensor) |

mg/m³ |

undiluted |

Smoke (AVL 415 Smoke Meter) |

mg/m³ |

|

Particle number in #/cm³ |

#/cm³ |

|

Particle number - Dilution Ration rd |

||

Ammoniac NH3 |

ppm |

|

CO2 (RAW) |

% or ppm |

Any CO2 signal. Measured on a dry basis. |

CO (RAW) |

ppm |

Any CO signal Measured on a dry basis. |

NOx (RAW) |

ppm |

Any NOx signal. Measured on a dry or wet basis. |

HC (RAW) |

ppm |

Any HC signal. Measured on a wet basis. |

Alternative to HC: HC propane equivalent (C3) in ppm (RAW) |

ppm |

Any HC (C3) signal |

CH4 |

ppm |

measured wet |

CH4 (RAW) |

ppm |

measured wet |

Only the emission components measured on a dry basis will be corrected with the Kw,r factor. It can be specified for Nox, if measured on a dry (cold) or wet (hot) basis.

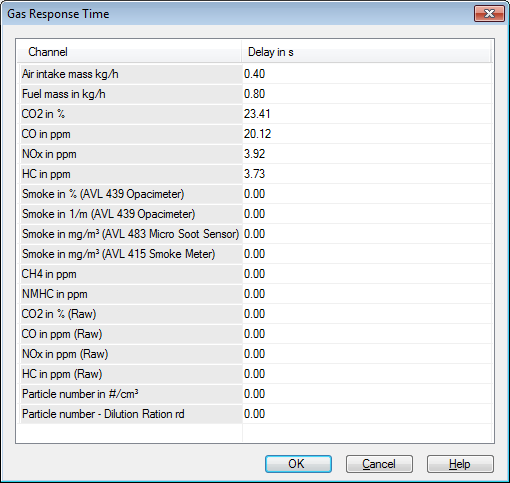

Gas Response Time¶

For transient cycles the gas response times in seconds can be specified. The data points are moved by the specified time.

Fuel Composition¶

The fuel composition can be set in mass per cent for 5 different components.

The fuel composition is used to calculate the NOx correction factor. as specified in ISO 16183, Formula 15 and Formula 18.

For CNG fuel the molar hydrogen ratio of the fuel can be specified. Default value is 4.0.

Template¶

An example template can be found in the \uniplot\addin\rs_emission

directory. The template has the file name etc_template-en.ipw.

Definition of Weight Factors for Stationary Tests¶

For the stationary test, the weight factors and the test limits are saved in a text file.

To edit the file, choose Emission Evaluation=>Configuration and click on the Open button. The file will be opened in an editor. All modifications can be used as soon as the file is saved. The file can be saved on a network drive.

An example file can be found in the addin directory (Default file).

Example for a Weight Factor File:

; Weight Factors for Steady State Test Cycles.

;

; Comments start with a semi colon in the first column.

;

; The order of the modes must match the order in the data file. The elements

; must be separated by a colon.

;

;Limit-HC in g/kWh

;Limit-NOx in g/kWh

;Limit-CO in g/kWh

;Limit-PM in g/kWh

; LimitName: Euro III, Euro IV, Euro V specifies the correction factor calculation.

[EURO III]

CycleType = ESC

LimitName = Euro III

Limit-CO = 2.1

Limit-HC = 0.66

Limit-NOx = 5.0

Limit-PM = 0.1

Limit-Smoke = 0.8

Weight-Factor = 0.15; 0.08; 0.10; 0.10; 0.05; 0.05; 0.05; 0.09; 0.10; 0.08; 0.05; 0.05; 0.05

[EURO IV]

CycleType = ESC

LimitName = Euro IV

Limit-CO = 1.5

Limit-HC = 0.46

Limit-NOx = 3.5

Limit-PM = 0.02

Limit-Smoke = 0.5

Weight-Factor = 0.15; 0.08; 0.10; 0.10; 0.05; 0.05; 0.05; 0.09; 0.10; 0.08; 0.05; 0.05; 0.05

The limit name is enclosed in square brackets. Each definition must specify the limitations for CO, HC, NOx, PM in g/kWh. The Limit-Name is a text that will be displayed in the report. For the ESC cycle the element LimitName also specified the regulation that is used to calculate the correction factors: Possible values: Euro III, Euro IV or Euro V.

The weight factors are separated by a semi-colon. The number of elements must match the number of data points and the order in the data file.

Verification of the test run (Regression Analysis)¶

In order to validate a test run, a regression analysis between the reference and the actual speed, torque and power values is executed. The regression analysis can be preformed with 1Hz or with the measured frequency. If the option 1 Hz is selected, the data is interpolated to 1 Hz using a linear interpolation.

The time lag between the actual and reference speed, torque and power values is calculated so that the regression results are minimized.

For the NRTC Cycle the first 25 seconds and last 25 seconds are ignored in the regression analysis.

If the regulation expects full load demand or no load demand. The following values of the throttle position are used:

Full load demand: Throttle Position is > 95%

No load demand: Throttle Position is < 5%

Permitted point deletions from regression analysis: Only those points are deleted from the regression analysis if the difference between the reference and the feedback value is greater than a tolerance of 1% of the maximum value.

Speed reference values: If the reference speed if smaller than 50% of the idle speed it will be set to idle speed. See Regulation No. 49, Revision 5.

For the WHTC-Test, the torque values are deleted for the for minimum and maximum operator demand (criteria 3 and 4).

WHTC Point Deletions: For Minimum operator Demand (idle point)) a window of +-0.5% is used and for Torque a window for +- idle torque is used.

WHTC Test:

For the “Minimum operator demand” and “Maximum operator demand” (Regulation No. 49, Revision 5) either torque or speed points can be omitted. Only those points will be removed from the statistic which are not in a range of 1% around the 45° line. The tolerance is 1% of the maximum torque or the maximum speed.

In a first step all points which are outside the tolerance for torque will be removed. If not all omitted points are used, the remaining points will be applied for speed.

Loading the measured data¶

Negative values for the emission channels are set to 0.

Configuration¶

Calculation¶

Calculation of the Saturated vapor pressure for water:

// T_C in grad C

T_K = T_C + 273.15;

ln_Pe = -6096.9385 ./ T_K + ...

21.2409642 - ...

2.711193e-2 .* T_K + ...

1.673952e-5 .* T_K .* T_K + ...

2.433502 .* log(T_K);

p = exp(ln_Pe) ./ 100 ; // hPa = mbar

Source: Sonntag (1994), JE05-Cycle Documentation

Absolute humidity of the intake air (g water per kg dry air):

// Ha=humidity of the intake air, g water per kg dry air

// Ha=(6.220 * Ra * pa)/(pB-pa * Ra * 10-2)

// Ra=relative humidity of the intake air, %

// pa=saturation vapor pressure of the intake air, kPa

// pB=total barometric pressure, kPa

Ra = rv_hyg_percent;

pa = rv_pw_mbar/10;

pB = rv_barom_hPa/10 - rv_p_air_intake_mbar/10;

ha = 6.22 .* Ra .* pa ./ (pB - pa .* Ra ./ 100);

If the relative humidity is measured in the intake manifold, the relative air pressure in the intake pipe should be specified.

NOx correction for humidity and temperature¶

As the NOx emission depends on ambient air conditions, the NOx concentration shall be corrected for ambient air temperature and humidity with the factors given in the following formulae.

Euro I und II (Diesel):

// 88/77/EWG, (3.12.1987)

// http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:1988L0077:19911011:DE:PDF

rv_a1 = 0.044 * rv_q_mf_kg_h ./ g_air_dry - 0.0038;

rv_a2 = -0.116 * rv_q_mf_kg_h ./ g_air_dry + 0.0053;

rv_a4 = (1 + rv_a1 .* (7 * rv_ha - 75)) + rv_a2 .* ((rv_ta_celsius + 273.15)-302);

rv_nox_factor_euro_1_2 = 1 / rv_a4;

// Datei ist:

// rv_ha (m) = Feuchte der Ansaugluft, ausgedrückt in g Wasser pro kg trockener Luft,

// rv_ta_celsius = Temperatur der Luft in °C,

// rv_q_mf_kg_h ./ g_air_dry (GFÜL / GAIR) = Kraftstoff-Luft-Verhältnis (Trockenluft).

Euro III (Diesel):

// L275/61 (20.10.2005), Para 4.3

// http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:31997L0068:EN:HTML

// 1.3.3. Humidity correction for NOx

rv_a1 = 0.309 * rv_q_mf_kg_h ./ g_air_dry - 0.0266;

rv_a2 = -0.209 * rv_q_mf_kg_h ./ g_air_dry + 0.00954;

rv_a4 = (1 + rv_a1 .* (rv_ha - 10.71)) + rv_a2 .* ((rv_ta_celsius + 273.15)-298);

rv_nox_factor_euro_3 = 1 / rv_a4;

Euro IV, V (Diesel):

// 1999/96/EG, (13.12.1999), Page. 74

// http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2004:225:0003:0107:EN:PDF

// 2.1.2.3. NOx correction for humidity and temperature

rv_nox_factor_euro_4_5 = 1 / (1 - 0.0182 .* (rv_ha - 10.71) + ...

0.0045 .* ((rv_ta_celsius + 273.15)-298));

Euro VI (Diesel):

// Diesel

// E/ECE/324/Rev.1/Add.48/Rev.5 Page 292

// http://www.unece.org/fileadmin/DAM/trans/main/wp29/wp29regs/R049r5e.pdf

// compression-ignition engines

rv_nox_factor = 15.698 * rv_ha ./ 1000 + 0.832;

// positive ignition engines (CNG)

// ISO 16183, Formula 24

rv_nox_factor = 0.6272 + 44.030 * 0.001 * rv_ha - 0.862 * 0.001 * (rv_ha .* rv_ha);

Dry / wet correction for CO-, CO2- and NOx¶

The measured concentration shall be converted to a wet basis according to the following formulae:

Euro I, II (Diesel):

// 88/77/EWG (3.12.1987)

// http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:1988L0077:19911011:DE:PDF

// Page 61

rv_conox = 1 - (1.85 * rv_q_mf_kg_h) ./ g_air_dry;

// Dabei ist:

// rv_q_mf_kg_h (GFUEL) = FKraftstofffluß in kg/h (kg/s)

// g_air_dry (GAIR) = der Luftstrom (kg/h) (kg/s) (Trockenluft)

Euro III (Diesel):

// Richtlinie 99/96/EG

// http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2000:044:0001:0155:DE:PDF

// Seite 61

Ffh = 1.969 ./ (1 + (rv_q_mf_kg_h ./ g_air_wet));

Kw2 = 1.608 .* rv_ha ./ (1000 + (1.608 .* rv_ha));

rv_conox = 1 - Ffh .* (rv_q_mf_kg_h ./ g_air_dry) - Kw2;

Euro IV, V (Diesel):

// vapour mass in air intake in kg/h

g_air_dry = rv_q_maw_kg_h ./ (1 + rv_ha/1000);

XFuel_Air = rv_q_mf_kg_h ./ g_air_dry;

// ISO 16183 / 5.5.5: Dry/wet correction, Formula 18

Fuel_KF = 0.055584 .* obj.fuel.FuelPercentH - 0.0001083 * obj.fuel.FuelPercentC - ..

0.0001562 * obj.fuel.FuelPercentS + 0.0079936 * obj.fuel.FuelPercentN + ..

0.0069978 * obj.fuel.FuelPercentO;

rv_conox_factor_euro_4_5 = (1 - ..

((1.2434 .* rv_ha + 111.12 .* obj.fuel.FuelPercentH .* XFuel_Air) ./ ..

(773.4 + 1.2434 * rv_ha + XFuel_Air .* Fuel_KF*1000))) * 1.008;

Euro VI (Diesel):

// vapour mass in air intake in kg/h

g_air_dry = rv_q_maw_kg_h ./ (1 + rv_ha/1000);

XFuel_Air = rv_q_mf_kg_h ./ g_air_dry;

// http://www.unece.org/fileadmin/DAM/trans/main/wp29/wp29regs/R049r5e.pdf

// (Regulation No. 49 - Rev.5)

Fuel_KF = 0.055594 * obj.fuel.FuelPercentH + ..

0.0080021 * obj.fuel.FuelPercentN + ..

0.0070046 * obj.fuel.FuelPercentO;

rv_conox_factor = (1 - ..

((1.2434 .* rv_ha + 111.12 .* obj.fuel.FuelPercentH .* XFuel_Air) ./ ..

(773.4 + 1.2434 * rv_ha + XFuel_Air .* Fuel_KF*1000))) * 1.008;

NRTC, NRSC (Diesel):

// co/hc dry/wet correction for NRTC and NRSC

// http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2004:225:0003:0107:DE:PDF

co_dry_percent = co_dry_ppm / 10000;

rvkw2 = (1.608 * rv_ha) ./ (1000 + (1.608 * rv_ha));

rvkw = 1 / (1 + 1.88 * 0.005 * (co_dry_percent + co2_dry_percent) + rvkw2);

Euro V, VI (CNG):

kw1 = 1.608 .* rv_ha ./ (1000 + (1.608 .* rv_ha));

a1 = 1.0 ./ (1.0 + rsAlpha .* 0.005 .* (c_co_percent + c_co2_percent))

rv_conox_factor_euro_4_5 = (a1 - kw1) * 1.008;

Determination of Particle Numbers:

N = medf / 1.293 * k *c_mean * f * 1e6

N = number of particles emitted over the test cycle,

medf = Mass of equivalent diluted exhaust over the cycle. For this variable

the value of Gedf of the particle measurement is used,

k = 1, calibration factor. It is expected that that this factor is

is applied internally within the particle number counter,

c_mean: average concentration of particles from the diluted exhaust gas

corrected to standard conditions (273,2 K and 101,33 kPa), particles per cubic

centimetre,

f = 1, mean particle concentration reduction factor.

ELR Test¶

European load response test

The “ELR test” is a test cycle of a sequence of load steps at 3 or 4 constant engine speeds. The smoke is determined by means of an opacimeter. For each load step the smoke peak is determined. Calculation of the final smoke value from the averaged data:

SV = (0.43 × SV_A) + (0.56 × SV_B) + (0.01 × SV_C)

The opacimeter should apply a Bessel filter to the smoke data as described in the regulation.

The data should be measured over time with a frequency of 20Hz or higher. Instead of transient data file, a file with 9 or 12 records with the results of each load step can be selected.

If a transient data file is selected, a second page with the smoke, speed and torque versus time curves is added to the result page.

Extracting the load steps for a transient data file¶

The signal length must be greater than 270 seconds (9 steps a 30 seconds)

2. The throttle signal must be below 70% for 10% load and above 70% for 100 % load.

The throttle signal must cross the 70% line at least 17 times.

4. The length of the 100 % load period has to be between 8 and 12 seconds long. The regulation expects between 9 and 11 seconds.

The length of the 10% load period has to be between 18 and 22 seconds long.

The data is only valid if at least 9 or 12 load steps are found.

Smoke Data Validation¶

As described in E/ECE/324/Rev.1/Add.48/Rev.5, Annex 4A - Appendix 1, Paragraph 3.4 Cycle validation is executed:

“The relative standard deviations of the mean smoke values at each test speed (SVA, SVB, SVC, as calculated in accordance with paragraph 7.3.3. of this appendix from the three successive load steps at each test speed) shall be lower than 15 per cent of the mean value, or 10 per cent of the limit value shown in table 1 of paragraph 5.2. of the Regulation, whichever is greater. If the difference is greater, the sequence shall be repeated until three successive load steps meet the validation criteria.”

and, if a 4th random test speed is measured:

“5.2.3.2.: The smoke value on the random test speed of the ELR shall not exceed the highest smoke value of the two adjacent test speeds by more than 20 per cent, or by more than 5 per cent of the limit value, whichever is greater.”

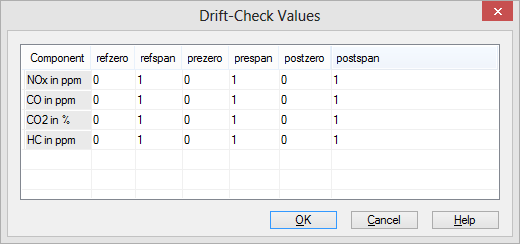

EPA 1065¶

The calculation can be executed with drift correction. If drift correction is enabled, the gas concentration for zero gas and span gas must be measured before and after the test according to regulation EPA § 1065.672 Drift correction . The values for the gas concentrations must be specified in the dialog box Drift Check Configuration:

The result values will be corrected with the calculated drift correction.

C-Balance¶

UniScript-Interface¶

UniScript-Interface:

ssXMLFile = _etc_get_settings_dir() + "nrtc_tuev3.xml";

ssTemplate = "Z:\\projects\\emission\\etc_template1.ipw";

etc_eval_test(ssXMLFile, ssTemplate)

The source code of the etc_eval_test() function can be found in the file

rs_emission\rs_main.ic.

XML Parameter File¶

Example for a parameter file:

<?xml version='1.0' encoding='utf-8'?>

<obj id='1'>

<string key='FileType'>UniPlot ETC-Parameter File</string>

<string key='Version'>2.0</string>

<obj id='2' key='PM'>

<string key='Enable'>1</string>

<string key='Gedf_kg_h'>3170.23</string>

<string key='Mf_mg'>0.53</string>

<string key='Msam_kg'>3.61</string>

<string key='T_c'>50</string>

</obj>

<obj id='3' key='PM_cold'>

<string key='Gedf_kg_h'>0</string>

<string key='Mf_mg'>0</string>

<string key='Msam_kg'>0</string>

<string key='T_c'>0</string>

</obj>

<number key='bRegression1Hz'>1</number>

<obj id='4' key='channel'>

<string key='air_intake_mass_kg_h'>Air_mass</string>

<string key='air_intake_pressure_mbar'>P_intake</string>

<string key='air_intake_temperature_gradC'>T_intake</string>

<string key='alpha_percent'>Load</string>

<string key='barom_hPa'>PAtmos</string>

<string key='ch4_ppm'>--Not Used--</string>

<string key='co2_percent'>CO2</string>

<string key='co2_raw_percent'>--Not Used--</string>

<string key='co_ppm'>CO</string>

<string key='co_raw_ppm'>--Not Used--</string>

<string key='dew_point_temp_c'>--Not Used--</string>

<string key='fuel_mass_kg_h'>Fuel_mass</string>

<string key='hc_c3_ppm'>--Not Used--</string>

<string key='hc_c3_raw_ppm'>--Not Used--</string>

<string key='hc_ppm'>HC</string>

<string key='hc_raw_ppm'>--Not Used--</string>

<string key='hyg_percent'>Humidity</string>

<string key='nh3_ppm'>--Not Used--</string>

<string key='nmhc_ppm'>--Not Used--</string>

<string key='nox_ppm'>NOx</string>

<string key='nox_raw_ppm'>--Not Used--</string>

<string key='particle_n_cm3'>--Not Used--</string>

<string key='particle_n_rd'>--Not Used--</string>

<string key='smoke415_mg_m3'>CO</string>

<string key='smoke_k'>Smoke_FSN_ge</string>

<string key='smoke_mg_m3'>Smoke_FSN_ge</string>

<string key='smoke_percent'>Smoke_FSN_ge</string>

<string key='speed_reference_rpm'>Speed_Ref</string>

<string key='speed_rpm'>Speed</string>

<string key='time_s'>Time</string>

<string key='torque_nm'>Torque</string>

<string key='torque_reference_nm'>Torque_Ref</string>

</obj>

<obj id='5' key='coolingfan'>

<string key='On'>1</string>

<string key='p'>Default, 4.6E-10, -1.9E-7, 1.3E-4, 5</string>

</obj>

<obj id='6' key='fuel'>

<number key='FuelPercentC'>86.5</number>

<number key='FuelPercentH'>13.5</number>

<number key='FuelPercentN'>0</number>

<number key='FuelPercentO'>0</number>

<number key='FuelPercentS'>0</number>

<string key='ssFuelName'>Diesel</string>

</obj>

<obj id='7' key='ref'>

<string key='cycle_name'>WHTC</string>

<string key='limit_name'>Euro VI</string>

</obj>

<obj id='8' key='response_time'>

<number key='air_intake_mass_kg_h'>0.40000000000000002</number>

<number key='ch4_ppm'>0</number>

<number key='co2_percent'>23.41</number>

<number key='co2_raw_percent'>0</number>

<number key='co_ppm'>20.120000000000001</number>

<number key='co_raw_ppm'>0</number>

<number key='fuel_mass_kg_h'>0.80000000000000004</number>

<number key='hc_ppm'>3.73</number>

<number key='hc_raw_ppm'>0</number>

<number key='nmhc_ppm'>0</number>

<number key='nox_ppm'>3.9199999999999999</number>

<number key='nox_raw_ppm'>0</number>

<number key='particle_n_cm3'>0</number>

<number key='particle_n_rd'>0</number>

<number key='smoke415_mg_m3'>0</number>

<number key='smoke_k'>0</number>

<number key='smoke_mg_m3'>0</number>

<number key='smoke_percent'>0</number>

</obj>

<string key='ssCertificationTest'>1</string>

<string key='ssEngineType'>Diesel Engine</string>

<string key='ssFileName'>Z:\projects\emissionsauswertung\whtc_testdata.nc</string>

<string key='ssFileName_2'/>

<number key='ssFileName_2_Enable'>0</number>

<string key='ssIdleSpeed_rpm'>600</string>

<string key='ssIdleTorque_nm'>5</string>

<string key='ssMaxTorque_nm'>3100</string>

<string key='ssNCFile'>Z:\projects\emissionsauswertung\whtc_testdata.nc</string>

<string key='ssNCFile_2'/>

<string key='ssNOxHOT'>1</string>

<string key='ssRatedPower_kw'>200</string>

<string key='ssRatedSpeed_rpm'>2100</string>

<string key='ssSpeedMaxTorque_rpm'>1150</string>

<string key='ssTurboChargedType'>1</string>

</obj>

Result-Document¶

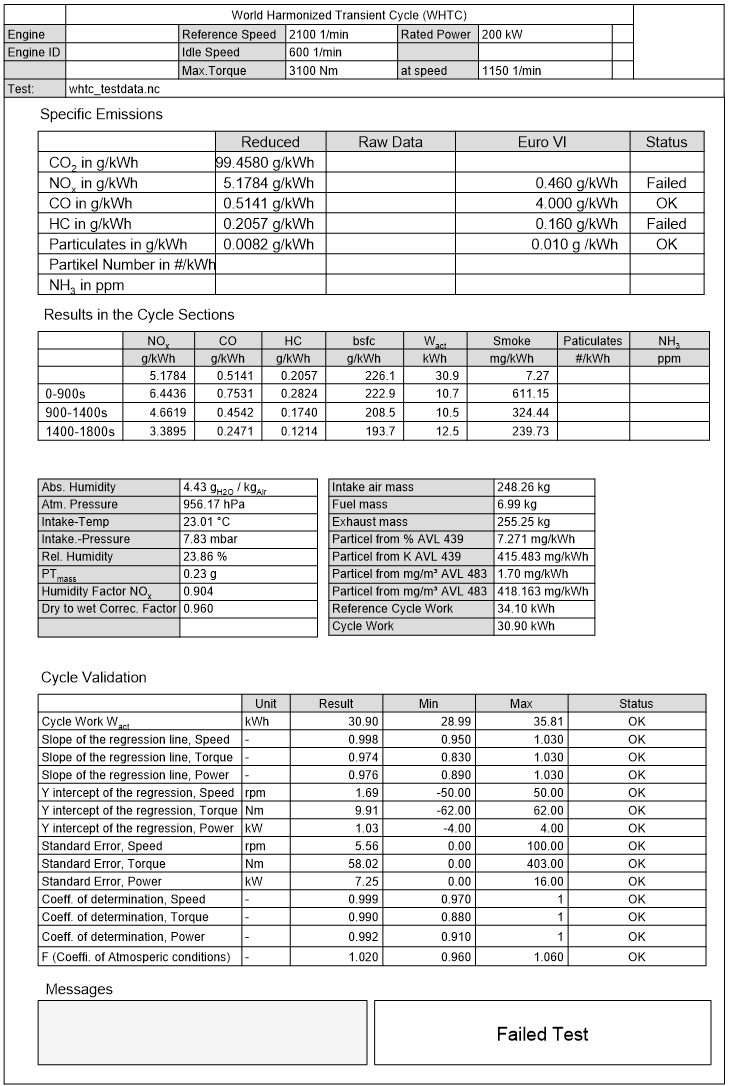

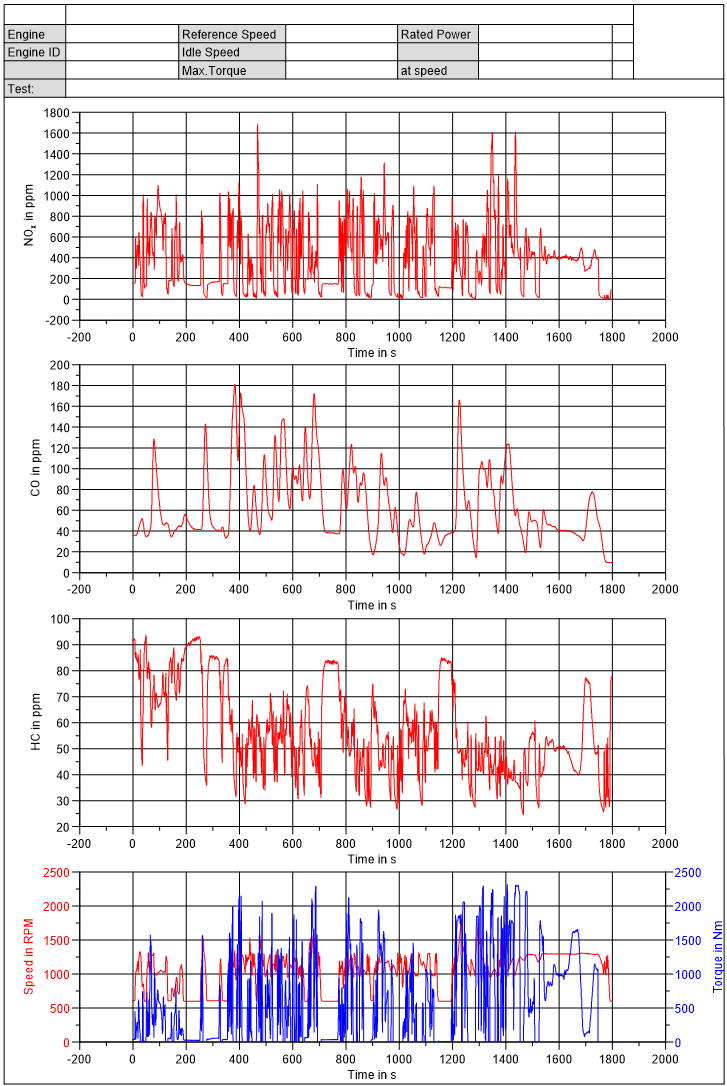

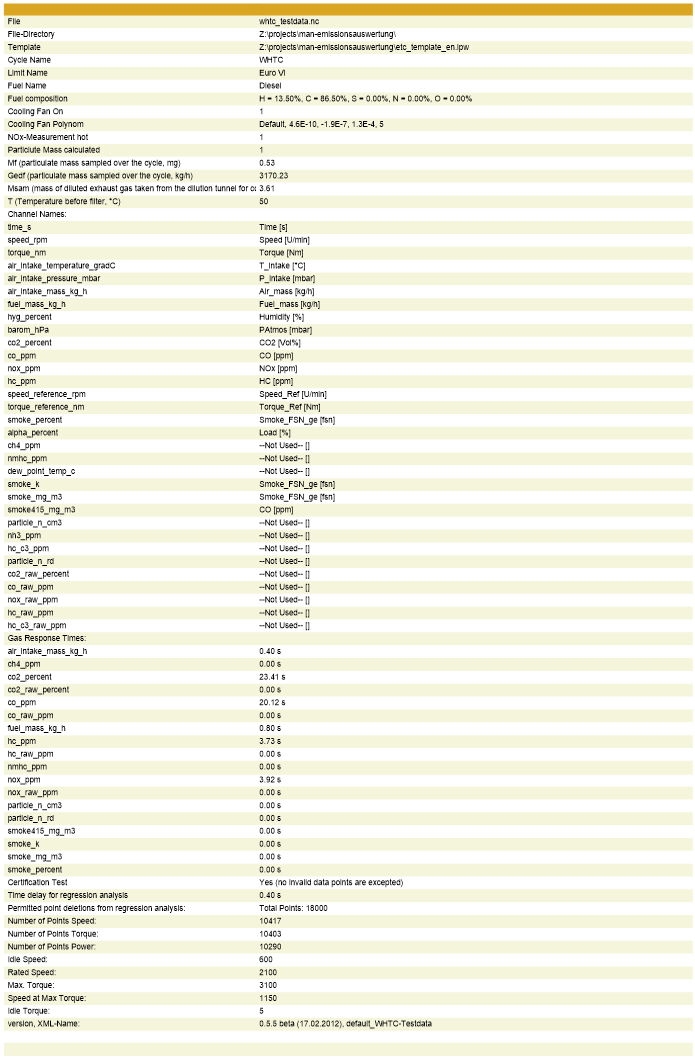

Here is the result of an WHTC test:

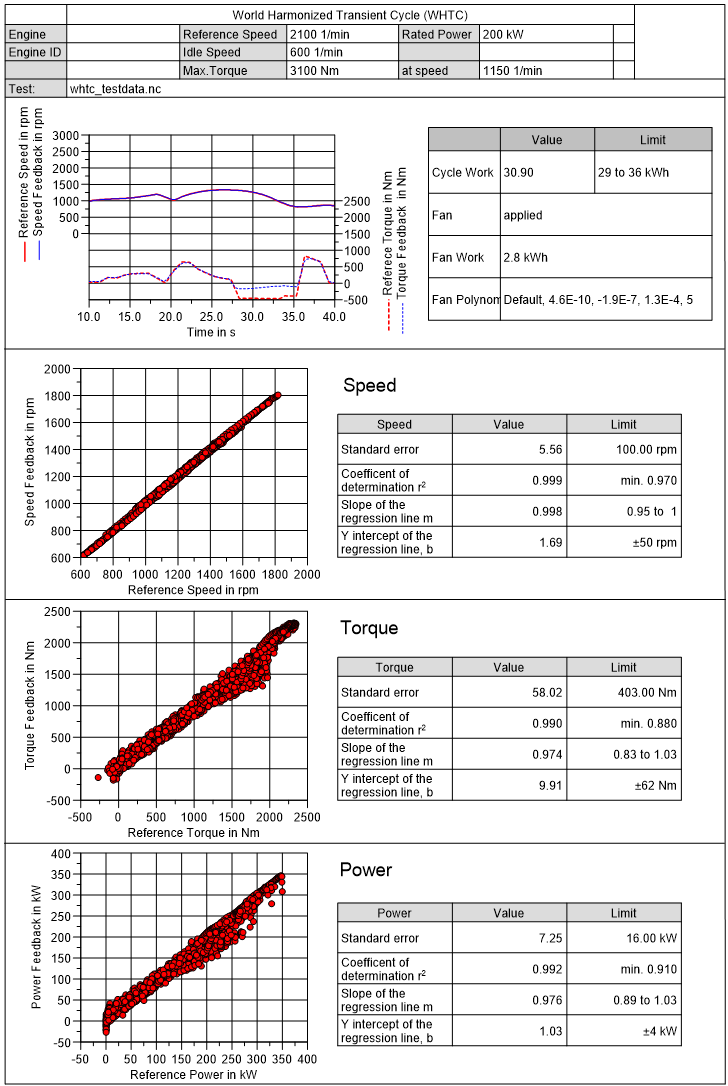

The verification page contains the results of the regression analyze:

The emission page contains diagrams with NOx, HC and CO results:

The parameter page contains all parameters:

Problems¶

If you have any problems using the addin do not hesitate to contact us.

id-1940897